4 Axis Processing Center

- Price: Get Latest Price

- Shipping Port: Qingdao Port / According to your request

- Payment: T/T, ACH, Fedwire, SEPA, PayPal, Credit Card

- Packing: Standard Packing

Contact Us to Ask A Free Quote !

Get Latest Price

Fill below form to get the latest price now!

Product Details

Features

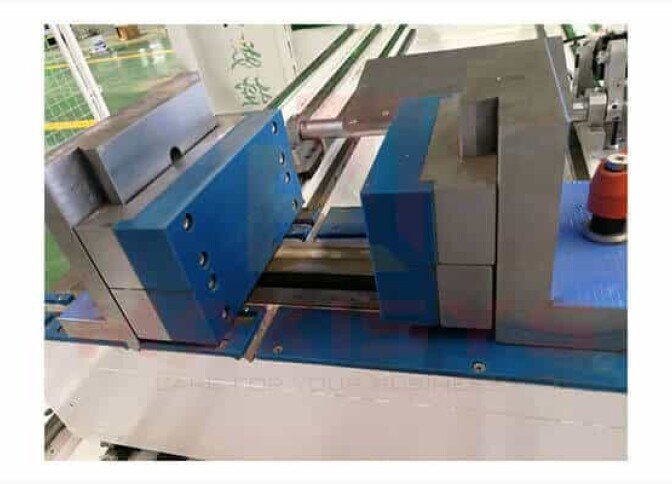

4 Axis Processing Center Description

This 4 Axis Processing Center uses the moving beam, moving column gantry frame structure. It works more smoothly and stable and improves the machine processing rigidity.

Suitable for complex parts processing which uses all kinds of aluminum, copper, uPVC, and also industrial profile.

It could finish multi-procedure processing such as milling, drilling, and also tapping with one-time clamping.

This 4 Axis Processing Center adopts imported well-known brand, easy to operate. Use high-end CNC control systems, such as Germany Siemens or Italy Osai.

This machine also adopts imported servo motor, ball screw, linear guide rail, and bearing. These could ensure machine processing more accurate, more stable, and also more reliable.

This machine uses high precision linear guide rail, ball screw, rack and pinion, and imported servo motor. These could ensure the movement smoothly and stable and keep positioning and processing more accurate.

The feeding movement is pre-stretched to ensure the stability of the machining accuracy.

We use the imported 5 axis milling head to finish all surfaces processing beside the bottom at any angle.

Automatic milling cutter changing with row-knife-type. Optional: vertical disco tool magazine.

The automatic lubrication system could lubricate the machine with a fixed quantity at a regular time. This will also ensure the stability of the machine accuracy.

This machine uses a pneumatic clamping table to improve the loading speed. Optional: T-type table.

This machine adopts imported Renishaw interferometer detection to compensate the machine accuracy.

Parameters

| Voltage | 380V/50HZ |

|---|---|

| Main spindle power | 12KW |

| Air resource pressure | 0.6-0.8Mpa |

| Travel X-axis | 7000mm(customized) |

| Travel Y-axis | 1400mm |

| Travel Z-axis | 550mm |

| Speed X-axis | 0-60m/min |

| Speed Y-axis | 0-30m/min |

| Speed Z-axis | 0-20m/min |

| Y/Z positioning error | ±0.02mm |

Image Gallery

Video Gallery

Playlist

FAQs

Normally use nude packing if use FCL. But I suggest you use plate packing or box packing to keep the machines safer. This will need extra charges. But not cost so much and make sure the machine safety.

We can help you to arrange all the things. What you do is just let us know which seaport is near you.

This should accord which machine you choose and if the machines have stock. Generally speaking, it will be 10-30 days according to a different situation.

T/T 30% as deposit and 70% balance after the machine ready for delivery. And other payments also available. Please not hesitate to contact us directly for more information.

We can supply FOB, CIF, and CNF. You can choose a different item according to your condition.

Yes. sure we can. We will send our experienced engineers to your factory to help you install the machines and train your workers until they produce the standard products.

12 months. In the period of the guarantee, if there are damages without wrong human operation, we will replace or repair them in free exception of wearing parts and consumptive parts.

Besides the quality machines, we will give our clients all-around services and whole consultancy. Through talking with each other I think as a customer you can truly feel our professional services.

Moxisys use world famous spare parts on all the machine. one is to guarantee the machine quality and the other is that once the machine spare parts have some problem you can change it easily from your local market.

They are mechanical processing parts. They are the main structure of the machines. Such as the machines’ head, base and some other parts which consist of the main part of the machine. They like human’s bones supporting the entire machine and coordinate the spare parts work smoothly. And only the good mechanical processing parts coordinate good quality spare parts, then they are called quality machines.